As an interior designer, I’ve always been fascinated by the interplay of form and function in architecture. Today, I’m thrilled to share my insights on a topic that’s revolutionizing the way we think about concrete construction: structural fabric formwork.

This isn’t just about building techniques; it’s about reimagining the very foundations of our living spaces and pushing the boundaries of what’s possible in design. So, let’s dive into this exciting world where fabric meets concrete!

Introduction to Structural Fabric Formwork: Weaving a New Narrative in Construction

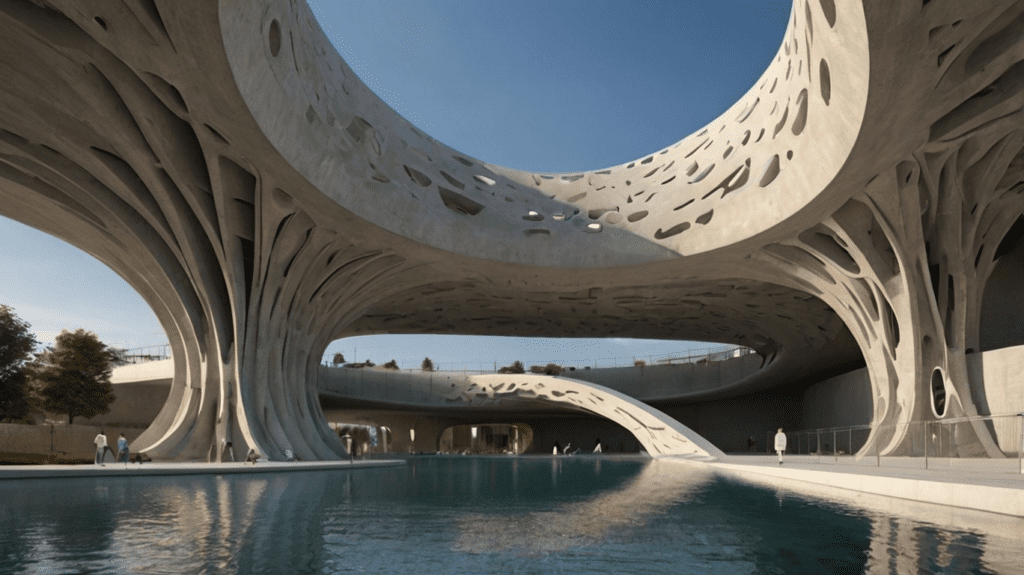

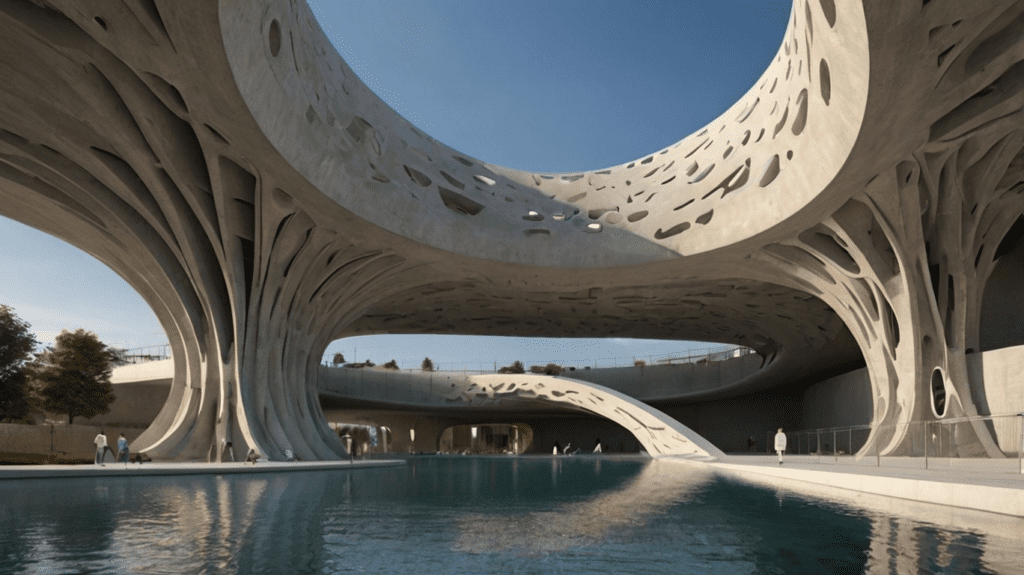

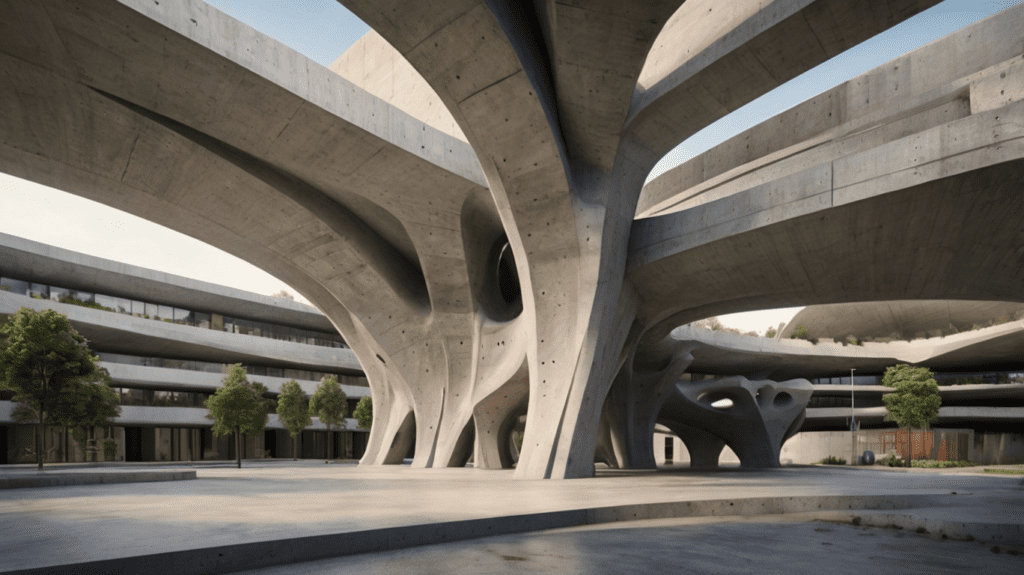

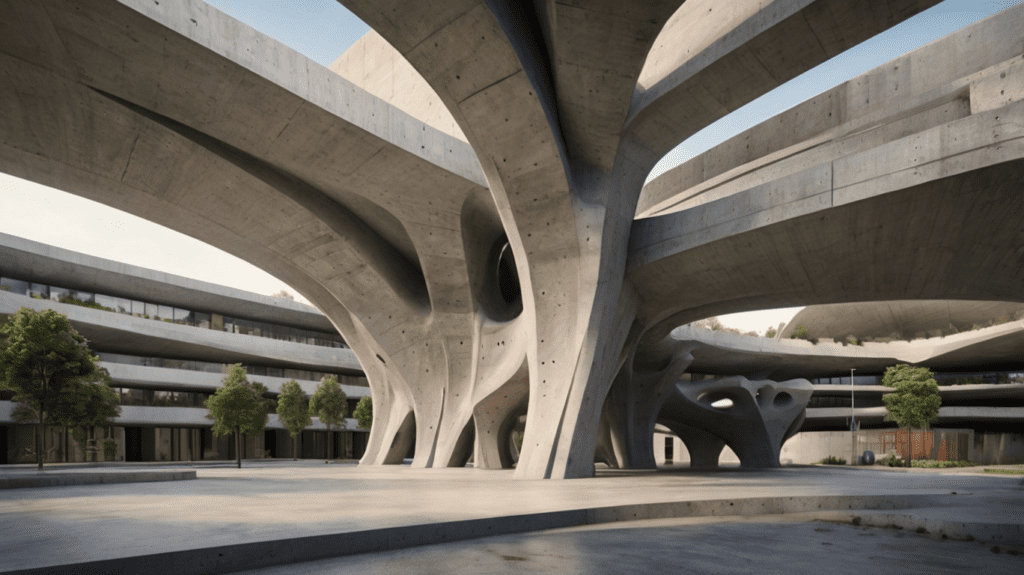

Imagine a world where concrete structures flow like fabric in the wind, where buildings seem to defy gravity with organic, fluid forms. This isn’t a scene from a sci-fi movie; it’s the reality that structural fabric formwork is bringing to life.

As someone who’s spent years creating beautiful interiors, I’ve always been constrained by the rigid forms of traditional construction. But fabric formwork? It’s like giving a sculptor a new, magical clay to work with.

Structural fabric formwork is exactly what it sounds like – using fabric as a mold for casting concrete. But it’s so much more than that. It’s a game-changer that’s addressing the need for innovation in an industry that’s been stuck in its ways for far too long. As we face increasing pressure to build more sustainably and efficiently, fabric formwork offers a breath of fresh air – or should I say a fresh pour?

Traditional Concrete Formwork: The Old Guard

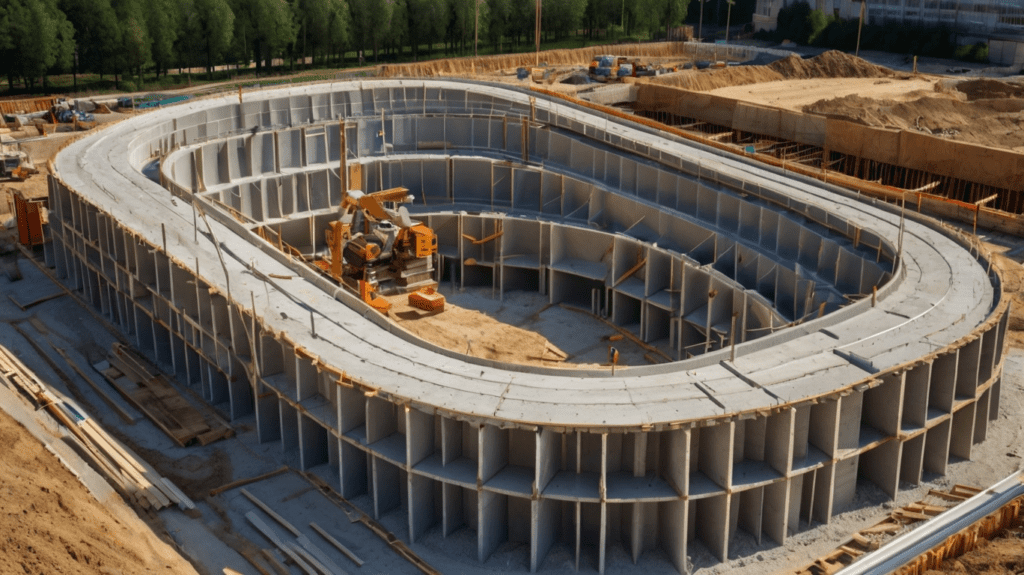

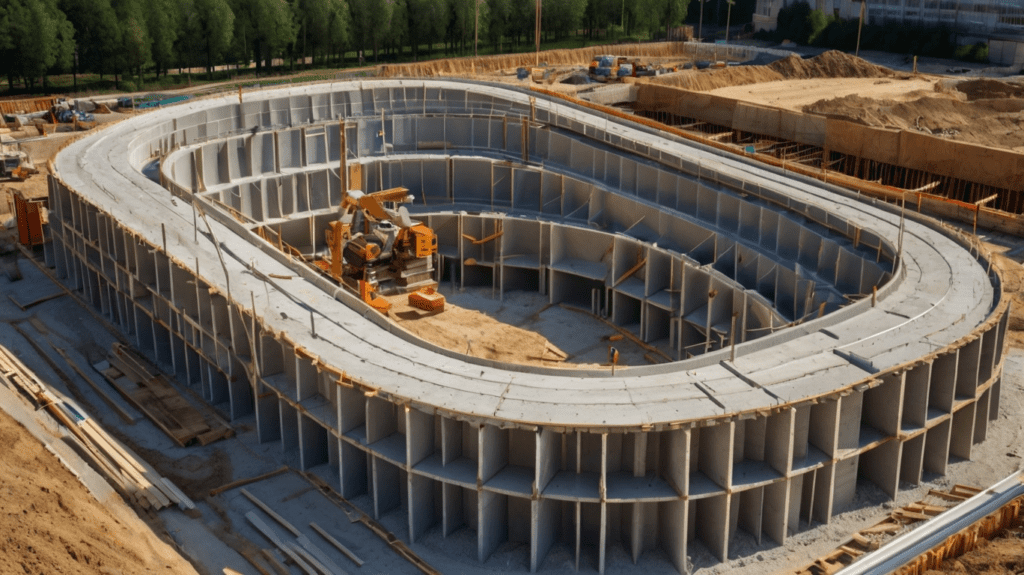

Before we dive into the fabric revolution, let’s take a moment to appreciate (and critique) the old ways. Traditional concrete formwork typically involves rigid materials like wood, steel, or plastic. Think of it as a giant, heavy, and often wasteful mold.

I remember working on a renovation project where the amount of wood wasted on formwork was heartbreaking not to mention the limitations it placed on design. Curves? Organic shapes? Forget about it – unless you have an unlimited budget and a lot of time on your hands.

The challenges of traditional formwork are numerous: it’s resource-intensive, time-consuming to set up and take down, and it limits the forms we can create. It’s like trying to paint a masterpiece with only a ruler and a pencil – possible, but oh so limiting.

Understanding Structural Fabric Formwork: The Fabric of Innovation

So, what exactly is structural fabric formwork? At its core, it’s a method of casting concrete using flexible, permeable fabric as the mold. But it’s so much more than that. It’s a way of letting concrete find its own form, guided by the laws of physics and the creativity of the designer.

The fabrics used aren’t your average bedsheets. We’re talking about specially designed textiles that can withstand the pressure of wet concrete while allowing excess water to escape, resulting in stronger, more durable concrete. Materials like geotextiles, polyolefin mesh fabrics, and even recycled materials are being used to create these innovative forms.

The History and Evolution of Fabric Formwork: From Fringe to Frontier

The idea of using fabric to shape concrete isn’t entirely new. In fact, the concept dates back to the 1960s, with pioneers like Spanish architect Miguel Fisac experimenting with flexible formwork. But it’s only in recent years that the technique has really taken off.

I remember attending a conference about a decade ago where fabric formwork was presented as a fringe concept. Fast forward to today, and it’s being used in projects around the world, from sculptural art pieces to functional structures. The evolution has been nothing short of remarkable.

How Structural Fabric Formwork Works?

The process of casting concrete in fabric is a beautiful dance of force. The fabric is suspended or stretched into the desired shape, and then filled with concrete. As the concrete is poured, the fabric stretches and bulges, creating organic, efficient forms that are incredibly strong.

One of the most fascinating aspects is the use of tension-activated formwork systems. These use the weight of the concrete itself to create the final form. It’s like watching a sculpture come to life, with the fabric guiding the concrete into shapes that seem to defy traditional construction logic.

Advantages of Structural Fabric Formwork: A Designer’s Dream

- Creates more with less: as an interior designer, I’m always looking for ways to create more with less. Fabric formwork delivers this in spades. The material efficiency is staggering – up to 70% less concrete can be used compared to traditional methods, without compromising strength.

- Highly Aesthetic: it’s the aesthetic possibilities that really get my creative juices flowing. Imagine columns that curve and flow like tree trunks, walls with subtle, organic textures, and structures that seem to grow from the ground. It’s opened up a whole new world of design possibilities.

- The improved concrete quality is another huge plus. The fabric allows excess water to escape, resulting in denser, stronger concrete. And let’s not forget the cost savings – less material, less labor, and often faster construction times. It’s a win-win-win situation.

Challenges and Limitations of Structural Fabric Formwork

Of course, no revolutionary technique comes without its challenges. There’s a significant learning curve involved in working with fabric formwork.

- It requires a different way of thinking about construction, and skilled workers need to be trained in these new techniques.

- Regulatory issues can also be a headache. Building codes often lag behind innovative techniques, and getting approval for fabric-formed structures can be an uphill battle. I’ve been involved in projects where educating local officials about the structural integrity of fabric-formed concrete was half the battle.

- Scalability is another concern. While fabric formwork works beautifully for smaller structures and architectural elements, using it for large-scale construction projects presents unique challenges that are still being worked out.

Environmental Impact and Sustainability: Concrete Goes Green

In an age where sustainability is no longer optional, fabric formwork shines. The reduced material use translates directly into a lower carbon footprint. Less concrete means less cement production, which is a major contributor to global CO2 emissions.

Moreover, many of the fabrics used can be recycled or reused. I worked on a project where we repurposed the fabric forms into decorative elements within the finished space – talk about full-circle design!

Applications in Architecture and Design: Where Art Meets Engineering

This is where fabric formwork really sings. The ability to create organic, fluid shapes opens up a world of possibilities for architects and designers. I’ve seen stunning examples of fabric-formed columns that look like they’ve been sculpted by the wind and walls with undulating surfaces that play with light in mesmerizing ways.

One project that stands out in my mind is a small chapel we worked on. The client wanted something unique and spiritually uplifting. Using fabric formwork, we created a series of curving walls that seemed to reach towards the sky. The play of light on the subtly textured concrete surfaces throughout the day was nothing short of magical.

Structural Performance and Engineering Considerations: Beauty with Brawn

Don’t let the flowing forms fool you – fabric-formed concrete can be incredibly strong. The optimization of form that occurs naturally in the fabric molding process often results in structures that are more efficient in terms of load distribution.

Reinforcement techniques have been developed specifically for fabric formwork. From simple rebar to more complex systems of cables and meshes, engineers are finding innovative ways to enhance the structural capabilities of these organic forms.

Structural Fabric Formwork in Infrastructure Projects: Beyond Buildings

It’s not just about beautiful buildings – fabric formwork is making waves in infrastructure projects too. I’ve seen fascinating applications in bridge construction, where fabric-formed piers and abutments not only look striking but also perform exceptionally well structurally.

In marine environments, fabric formwork really comes into its own. The ability to create complex underwater shapes without the need for dewatering is a game-changer. I once visited a coastal protection project where fabric-formed concrete units were used to create artificial reefs – not only functional but also providing a habitat for marine life.

DIY and Small-Scale Applications: Bringing Innovation Home

One of the most exciting aspects of fabric formwork is its accessibility. With some basic materials and a bit of know-how, even DIY enthusiasts can experiment with this technique. I’ve guided homeowners in creating unique garden features, from sculptural planters to curved benches, all using fabric formwork.

In educational settings, fabric formwork is a fantastic way to teach principles of structural engineering and design. I’ve participated in workshops where students create small-scale fabric-formed structures, learning about forces, materials, and form in a hands-on, engaging way.

Computational Design and Fabric Formwork: Where Tech Meets Textile

The marriage of computational design and fabric formwork is producing some truly mind-bending results. Advanced software allows designers to model and optimize fabric-formed structures, predicting how the fabric will deform under the weight of concrete and fine-tuning the final form.

3D modeling and form-finding techniques are pushing the boundaries of what’s possible. I’ve been involved in projects where we used parametric design tools to create complex, interconnected fabric-formed elements that would have been impossible to conceptualize manually.

Material Innovations in Fabric Formwork: The Cutting Edge

The development of specialized fabrics for concrete forming is an exciting field. From ultra-strong synthetic meshes to biodegradable options, material scientists are constantly pushing the envelope.

I’m particularly excited about the integration of smart textiles into formwork. Imagine fabric forms that can monitor the curing process of concrete in real-time, or that change shape in response to environmental conditions. The possibilities are endless.

Economic Implications for the Construction Industry: A Paradigm Shift

The potential for cost savings with fabric formwork is significant. Reduced material use, faster construction times, and less need for heavy machinery all contribute to lower overall costs. However, it’s important to consider the bigger picture.

As fabric formwork becomes more widespread, we’re likely to see shifts in the job market. While there may be less demand for traditional formwork carpenters, new opportunities are opening up for skilled fabric formwork technicians and designers who specialize in this technique.

Fabric Formwork in Developing Countries: Building a Better Future

One of the most heartening applications of fabric formwork is in developing countries. The low-tech nature of basic fabric-forming techniques makes it accessible in areas with limited resources. I’ve been fortunate enough to be involved in projects where fabric formwork was used to create affordable, durable housing in disaster-struck regions.

The empowerment aspect is huge. By teaching local communities these techniques, we’re not just building structures – we’re building skills and opportunities. It’s a perfect example of how innovative construction methods can have a direct, positive impact on people’s lives.

Future Prospects and Research Directions: The Sky’s the Limit

The future of fabric formwork is bright and full of possibilities. Ongoing research is exploring everything from new materials to automated fabric-forming processes. I’m particularly excited about the potential for combining fabric formwork with other cutting-edge technologies like 3D printing and robotics.

As for mainstream adoption, we’re seeing more and more large-scale projects incorporating fabric-formed elements. While it may not replace traditional methods entirely, I believe fabric formwork will become an essential tool in the construction toolkit of the future.

Comparison with Other Innovative Formwork Techniques: A Fabric in a Sea of Innovation

While fabric formwork is revolutionary, it’s not the only game in town when it comes to innovative forming techniques.

- 3D printed formwork, for instance, offers incredible precision and the ability to create complex geometries. However, it often lacks the organic, fluid qualities that fabric formwork excels at.

- Inflatable formwork systems are another interesting alternative, particularly for creating large, dome-like structures. But they can’t match the fine detail and textural qualities that fabric formwork can achieve.

In my experience, each of these techniques has its place, and the most exciting projects often combine multiple innovative approaches.

Maintenance and Longevity of Fabric-Formed Structures: Built to Last

A common concern with any new construction technique is durability. The good news is that fabric-formed concrete structures, when properly designed and executed, can be just as durable as traditionally formed concrete – if not more so.

The denser concrete resulting from the fabric-forming process often leads to increased resistance to weathering and erosion. However, as with any concrete structure, proper maintenance is key. I always advise clients to treat their fabric-formed concrete elements with the same care they would any other high-quality building material.

Conclusion: Shaping the Future, One Fold at a Time

As we wrap up this exploration of structural fabric formwork, I can’t help but feel excited about the future of construction and design. This technique represents more than just a new way of shaping concrete – it’s a new way of thinking about our built environment.

From the stunning aesthetic possibilities to the environmental benefits, from the potential for more affordable housing to the creation of more efficient structures, fabric formwork is truly revolutionary. It challenges us to rethink our assumptions about how buildings should look and how they should be made.

As an interior designer, I’ve always believed that our surroundings shape our experiences and our lives. With fabric formwork, we have a tool to create spaces that are not just functional, but inspiring; not just sturdy, but graceful; and not just efficient, but beautiful.

So the next time you see a building with curves that seem to defy gravity or a structure that looks like it grew organically from the earth, take a closer look. You might just be witnessing the fabric of construction’s future.